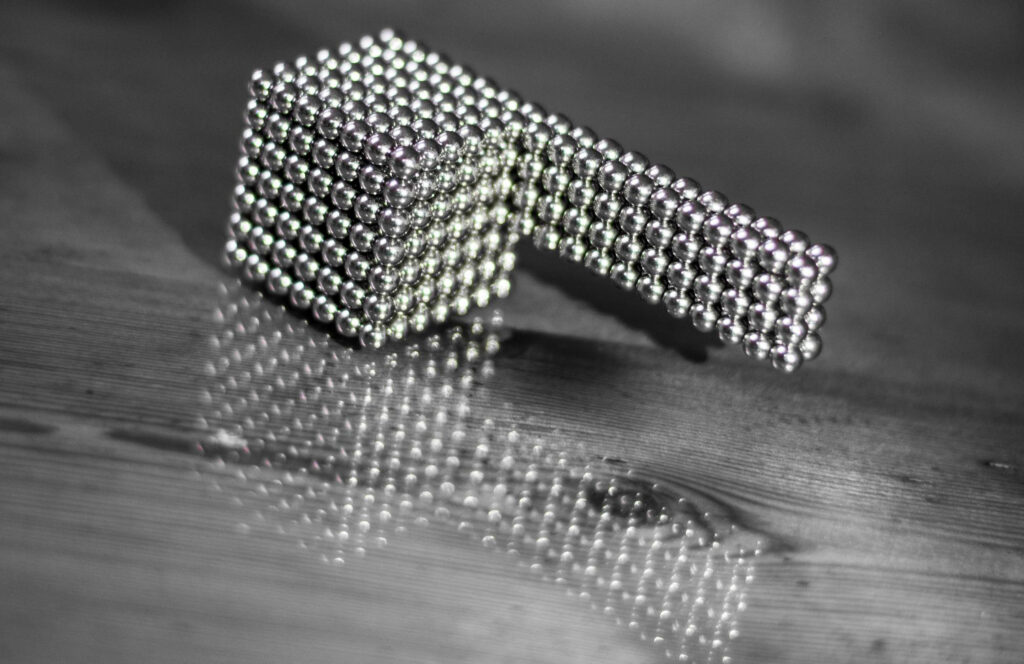

Neodymium magnet is a strong magnetic material created by combining neodymium, one of the rare earth elements, with iron and boron. Offering exceptional magnetic attraction despite their small size, these magnets play a critical role in modern technology and industrial applications.

Neodymium magnets attract attention not only with their strength but also with their long-lasting and durable structures. Thanks to their surface coating, they resist corrosion and oxidation and maintain their magnetic properties for a long time. For this reason, it stands out as one of the most important magnet types of modern technology and industrial applications.

What is Neodymium Magnet?

Neodymium magnet is a high-performance magnetic material produced from Ndfeb alloy formed by the combination of neodymium (Nd), iron (Fe) and boron (B) elements in special proportions. This type of magnet is considered one of the most powerful and energy dense types of modern magnet technology and the question “what is a neodymium magnet?” is curious.

Although it has small dimensions, it produces extraordinary attraction power and thanks to this feature, it is used as an indispensable component in many industrial and technological applications. Neodymium magnets maintain their magnetic field for a long time and do not lose magnetisation under normal conditions of use.

Special alloys and surface coatings used in the production process increase the magnet’s resistance to high temperatures and mechanical impacts. These coatings also provide protection against oxidation and corrosion. Surface coating is usually made with materials such as nickel, copper or epoxy. In this way, it exhibits a long-lasting performance even in environments with humid or chemical effects.

In addition, neodymium magnets, although mechanically fragile, can be safely used in industrial and technological fields with proper use and special designs. In some applications, these magnets can also be used for magnetic separation and particle control in systems such as water purification filters or water purifiers.

Where is Neodymium Magnet Used?

Neodymium magnets have a wide range of uses both in industrial applications and in everyday life. It is widely used in electronic devices, hard discs, speakers, headphones, microphones and computer components to improve the performance of magnets. These magnets contribute to the sensitive and stable operation of electronic components thanks to their magnetic field intensity. In medical applications, magnets play a critical role for accurate measurement and imaging in sensitive medical equipment such as MRI devices.

In industrial production facilities, neodymium magnets are used in tasks such as separating different materials in magnetic separation machines, safely holding heavy or sensitive parts in transport systems. These magnets increase productivity and allow production processes to be more controlled, especially in the automotive, energy and machinery sectors.

In the field of hobby and modelling, it offers safe and effective solutions with its high gravitational force despite its small size in robotic projects, electronic experiments and educational applications. High performance magnets provide design flexibility and allow users to develop more compact and functional products.

In the home and office environment, these magnets offer practical solutions in water purified dispensers, magnetic holders, hinge systems, cover mechanisms and vehicle accessories. Magnetic boards provide an organised use in office arrangement and educational applications and allow items to be held safely thanks to the high attraction power of the magnet.

What are the Neodymium Magnet Properties?

Neodymium magnets are characterised by their high energy density, which enables them to generate exceptional gravitational force even in small sizes. Therefore, it is possible to save space in design and offer compact but powerful magnetic solutions in engineering applications. Manufactured using Ndfeb alloy, these magnets are resistant to magnetic field loss and do not experience a significant decrease in performance even in long-term use.

They offer a stable magnetic field at room temperature, making them safe to use in sensitive applications such as electronic devices, motors and generators. The surfaces of neodymium magnets are usually coated with nickel, copper or epoxy. These coatings protect the magnet against corrosion and oxidation and increase its durability even in humid or chemically aggressive environments.

Thanks to the coating, the magnet becomes resistant to long-term and intensive use conditions. However, neodymium magnets have a mechanically fragile structure. Since they are sensitive to impacts or sudden pressure, they must be handled carefully during transport and assembly.

High temperature resistance is also one of the important features of neodymium magnets. Thanks to various alloys and special coatings, they can maintain their magnetic properties in certain temperature ranges. However, at extreme temperatures, the magnet may lose its magnetising power and its magnetic performance may permanently decrease. For this reason, the temperature tolerances of neodymium magnets in engineering and industrial applications are carefully considered and the type suitable for the application area is selected.

In addition, as high energy products, they provide superior performance in terms of energy density, attraction power and size ratio. These features enable the magnet to be used effectively in a wide range of fields such as industry, electronics, medical and scientific research. The ability to create a strong magnetic field despite its small size increases design flexibility and saves space. With its long-lasting and durable structure, neodymium magnets offer a reliable and efficient magnetic solution in technological and industrial applications.

Where is Neodymium Magnet Used?

Neodymium magnets are used safely in a wide variety of fields thanks to their high energy density and strong magnetic field properties. In the industrial sector, production lines, material handling systems and magnetic separation machines are equipped with neodymium magnets. These magnets provide high efficiency in processes such as separation, processing or safe transport of metal parts and accelerate work processes. Especially in the automotive, machinery and metalworking sectors, they offer strong magnetic attraction even in small sizes, allowing equipment to be more compact and efficient.

In the energy sector, neodymium magnets play a critical role to improve energy efficiency in generators, electric motors and turbines. By increasing the strength of the magnetic field, they optimise performance in power generation and conversion processes. This feature makes it possible to save energy and use long-lasting equipment in both renewable energy projects and power plants.

In electronic devices, neodymium magnets increase the performance of devices by providing a stable and strong magnetic field in computer hard discs, speakers, headphones, microphones and other sensitive electronic components. In the home and office environment, these magnets offer practical solutions in magnetic holders, hinge systems, cover mechanisms and vehicle accessories. Magnetic boards provide an organised use in office arrangement and educational applications and allow items to be held safely thanks to the high attraction power of the magnet.

In scientific research and educational applications, neodymium magnets are effectively used in force measurements in experimental setups, magnetic field intensity analyses and robotic projects. In research laboratories, magnets are preferred to obtain accurate and repeatable results in electromagnetic experiments. In addition, it can be safely used in treatment methods based on magnetic field applications in the medical field, magnetotherapy devices and various sensitive medical equipment. Thanks to their high performance and compact size, neodymium magnets stand out as a critical material that increases productivity in both industrial and scientific applications.

What are the Benefits of Neodymium Magnet?

The biggest advantage of neodymium magnets is that they can produce high magnetic power in small sizes. This provides flexibility in product design and saves space. Its durable structure provides long-lasting use and low maintenance. In industrial applications, it increases work efficiency by facilitating the adhesion and separation of materials. It contributes to energy saving while increasing the performance of electronic devices.

Provides precision and reliability in medical and scientific applications. It helps users achieve effective results with its ease of use and safety in the field of hobby and education. In addition, its corrosion-resistant structure makes it possible to use it safely for a long time in humid environments such as water treatment taps.

TR

TR

Blog

Blog